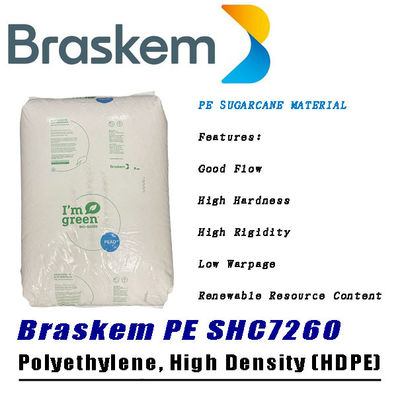

Green PE Material Braskem SHC7260 Bio Based Plastic HDPE Polyethylene Granules

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Density (23°C) | 0.959 G/cm³ | Melt Mass-Flow Rate (MFR) (190°C/2.16 Kg) | 7.2 G/10 Min |

|---|---|---|---|

| Notched Izod Impact (23°C) | 20 J/m | Durometer Hardness (Shore D) | 64 |

| Molding Temperature | 180 -190 °C | ||

| Highlight | Braskem SHC7260,Plastic HDPE Polyethylene Granules,Bio Based HDPE Polyethylene Granules |

||

Green PE material Braskem SHC7260 Bio-based plastic HDPE sugarcane polyethylene granules

Product description:

SHC7260 is a high-density polyethylene, developed for the injection molding which presents high hardness and stiffness, besides low tendency to warpage. Organoleptic properties are suitable for water caps applications. The minimum biobased carbon content of this grade is 94%, determined according to ASTM D6866.

Application:

Cosmetic packaging, Caps for water, Caps for non-carbonated or low carbonated soft drinks, toys, pallet

Sugarcane PE material, namely sugarcane polyethylene, is a plant-based plastic made from renewable raw materials such as sugarcane. Unlike traditional polyethylene that uses raw materials from fossil sources such as oil or natural gas, the manufacturing process of sugarcane polyethylene does not require the use of these fossil energy sources and has high environmental value.

The manufacturing process of sugarcane polyethylene mainly includes the conversion of biomass such as bagasse, corn starch, and cassava starch. After polymer chemical reactions, these biomasses are converted into polyethylene. This process not only reduces dependence on fossil fuels, but also helps reduce greenhouse gas emissions.

Sugarcane polyethylene has excellent physical properties and chemical stability, so it is widely used in medical, food, packaging and other fields. Especially in the field of food packaging, sugarcane polyethylene is better than traditional plastics in terms of moisture resistance, heat resistance, breathability, etc., and its degradability also meets environmental protection requirements. In addition, sugarcane polyethylene is 100% recyclable, which further reduces pollution to the environment.

Sugarcane is not only used to make polyethylene. Bagasse can also be used to make pulp and tableware. Its fibers have the advantages of moderate strength and toughness, which are suitable for making pulp molded products. These pulp products not only have good protection, but also their nestable and stackable characteristics can reduce storage costs.

Sugarcane PE material is an environmentally friendly and sustainable plastic material. Its wide application helps promote the development of green packaging and circular economy.

If you need more information about Braskem PE SHC7260, it is recommended to contact us directly for more information.

![]()

![]()

![]()