Lightweight PE Polyethylene Particles Low Temperature Heat Sealing Extrusion Grade

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| MFR | 1.5 G/10 Min | Durometer Hardness | 95A |

|---|---|---|---|

| Vicat Softening Temperature | 108 °C | Processing Temperature | 170°C-180°C |

| Highlight | PE Polyethylene Particles,Lightweight Polyethylene Particles |

||

| Blown film molding |

|---|

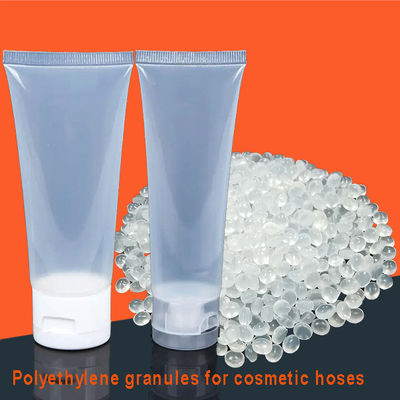

Polyethylene granules for low temperature heat sealing extrusion grade for cosmetic hoses

The following is an introduction to our materials:

Cosmetic hoses use polyethylene (PE) particles as raw materials, mainly because polyethylene has a series of excellent properties, making it suitable for manufacturing cosmetic packaging materials.

First of all, polyethylene particles are lightweight, with low density and light weight, making them easy to transport and use. This makes cosmetic hoses more convenient and economical during manufacturing and transportation.

Secondly, polyethylene particles have excellent high temperature resistance and can remain stable at higher temperatures. This is very important for the storage and transportation of cosmetics, ensuring that the hose maintains its shape and performance in various environments.

In addition, polyethylene materials also have certain light transmittance, pressure resistance and chemical stability, which are necessary properties for cosmetic packaging. At the same time, cosmetic hoses require material components not to contain harmful substances to ensure the safety and hygiene of the product.

The processability of polyethylene particles also plays an important role in the structural design and manufacturing of cosmetic hoses. Through specific processing techniques, polyethylene pellets can be processed into soft and elastic hoses, which facilitate the extrusion and distribution of products. At the same time, the opening of the hose can be equipped with a leak-proof design to prevent product leakage and oxidation.

In general, polyethylene particles are widely used in cosmetic hose manufacturing due to their excellent properties and processability. It can not only meet the basic requirements of cosmetic packaging, but also improve the safety and hygiene of products, providing strong support for the development of the cosmetics industry.

If you are interested in this product or have technical support or price inquiries, you can contact us by phone or email. No matter how you contact us, providing us with your product needs will help us serve you better. to you.

![]()

![]()

![]()