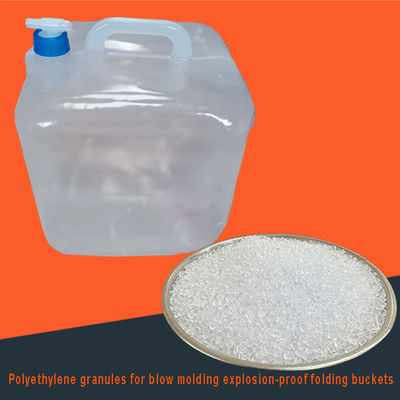

Blow Molding PE Polyethylene Granules For Explosion Proof Folding Bucket Car Water Bag

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| MFR | 0.3 G/10 Min | ESCR | 30.0 Hr |

|---|---|---|---|

| Durometer Hardness | 95A | Vicat Softening Temperature | 101 °C |

| Processing Temperature | 170°C-180°C | ||

| Highlight | Blow Molding Polyethylene Granules,PE Polyethylene Granules,Water Bag PE Granules |

||

| Blown film molding |

|---|

Blow molding explosion-proof folding bucket car water bag polyethylene granules for foldable water storage bottle

The following is an introduction to our materials:

The polyethylene pellets used in blow molding folding buckets are a vital raw material in the manufacturing process. The pellets have specific physical and chemical properties that make them suitable for use in the blow molding process to produce durable, lightweight and cost-effective buckets.

The blow molding process of polyethylene pellets typically involves heating the pellets to a molten state and then shaping them through a blow mold. In the mold, the molten polyethylene is blown up against the inner walls of the mold and forms the shape of a bucket as it cools. This process can produce buckets with excellent durability and sealing properties at relatively low cost, so it is widely used in the bucket manufacturing industry.

For blow molded folding buckets, the selection and quality of polyethylene pellets are crucial. High-quality polyethylene particles should have good melt fluidity, appropriate crystallinity and high mechanical strength to ensure the quality and performance of the final product. In addition, the environmental protection of polyethylene particles is also an aspect of increasing concern in modern manufacturing. Choosing particles that meet environmental protection requirements can help reduce environmental pollution during the production process.

When choosing polyethylene pellets, you need to consider multiple factors, including pellet specifications, quality, price, and the reputation of the supplier. At the same time, the optimal particle type and formula also need to be determined based on the specific blow molding process and product requirements.

In short, blow molded folding bucket polyethylene pellets are the key raw materials for manufacturing high-quality buckets, and selecting the appropriate pellet type and formula is of great significance to ensure the quality and performance of the final product.

If you are interested in this product or have technical support or price inquiries, you can contact us by phone or email. No matter how you contact us, providing us with your product needs will help us serve you better. to you.

![]()

![]()

![]()