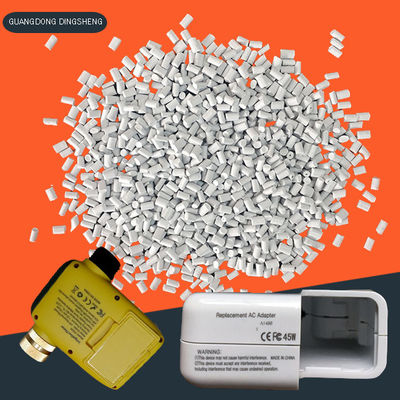

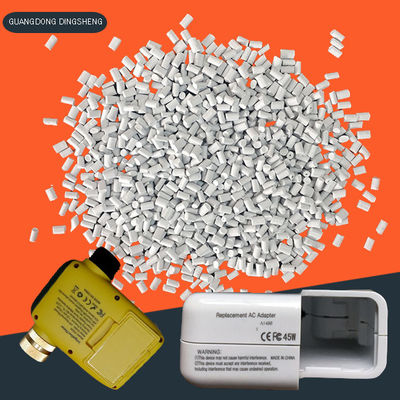

Nylon PA6 PC ABS Plastic Additives Laser Engraving Laser Marking Masterbatch

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | ABS Plastic Additives,Nylon PA6 Plastic Additives,Plastic Laser Marking Masterbatch |

||

|---|---|---|---|

Nylon PA6 ABS PC/ABS Laser Engraving Masterbatch Laser Masterbatch Laser Marking Additives Manufacturer![]()

![]()

A few things to note about laser engraving additives:

Flame retardants will affect the laser engraving effect, so the laser engraving effect of flame retardant plastics will be relatively poor, and even some special system flame retardant plastics cannot be laser engraved.

Black laser engraving powder can only be used for natural color materials. Black materials cannot be laser engraving because the black color of black materials will affect the laser engraving effect. This color material only needs to be added in an amount of 0.3% to achieve excellent carving effects. There is no need to add other black toner or black color and other dyeing auxiliaries during the production process, otherwise it will affect the laser engraving effect and even make it impossible to engrave. Black laser engraving powder can be used directly as black toner.

There is only one type of laser engraving masterbatch, the one with black characters. Masterbatch is suitable for any material. The effect of masterbatch is far better than that of laser engraving powder. The effect of laser engraving powder can never reach the effect of laser engraving masterbatch. For example, laser engraving masterbatch can be used to engrave QR codes, but laser engraving powder cannot.

When engraving black characters on white nylon, the effect of using laser engraving powder is poor, but there is no problem using laser engraving masterbatch.

White powder (white material engraved with black characters), as the name suggests, is laser engraving powder with black characters engraved on it. White powder can be used in materials with a variety of background colors, such as blue and black, yellow and black, etc.

PC/abs/PE/PP/PBT/pa6/pa66 special laser engraving powder masterbatch laser marking additives laser engraving additives white engraving black characters

Laser engraving powder is used in livestock ear tags, light switch covers, cosmetic packaging materials, car interior buttons and door handles, dashboards, ABS keyboards for commercial machines, PE, PET and PVC rigid containers and container covers, nylon PA66. 6 and PBT automotive and non-automotive electrical connectors, hood components such as fuse boxes and gas caps, anti-counterfeiting labels, container locks, stationery, home appliance casings, etc.

Product basic introduction

[Product name]: Laser carving powder

[Product Usage]: Suitable for PA, PBT (reinforced, flame retardant) and other materials.

[Product advantages]: It can make laser marking/coding on plastic surfaces smoother, and can be directly mixed with materials.

Product details

The Additives division is nationally recognized as a leader in color and additive solutions for the plastics industry. It is a key product item covering a comprehensive product line. The Additive Department provides and promotes a series of environmentally friendly pigments with environmental protection as the trade name, specifically meeting the adaptability and performance of plastic coloring.

1. The additive has excellent dispersibility, extremely low addition amount, and convenient color replacement. Our engineers have more than 20 years of experience in color matching and global procurement. They can select the most suitable products for customers, provide recommended formulas, and solve technical problems in production. In line with the trend of self-service color matching, we provide technical support to meet customer needs.

2. Product alias: laser additive, laser powder, laser engraving powder, laser powder, laser marking powder, laser marking additive, laser masterbatch, laser marking material, plastic laser marking powder, etc.

3. CM laser engraving powder can make plastic more easily marked/coded by laser, or greatly improve the clarity of laser marking of plastic materials. Where tiny marks could be formed in the past, high-definition marks can now be obtained. CM laser engraving powder is not only suitable for laser coding but also for laser welding.

The main function

1. It absorbs laser energy, converts the laser beam into thermal energy, and produces heating, carbonization, evaporation and chemical reactions on the plastic. For plastics with different chemical properties, there are different varieties of light laser marking on a dark background and dark laser marking on a light background.

2. Suitable for marking PP.PE.PVC.ABS.TPU.TPE.TPV.TPR.PBT.PET.PC.PA.POM.PEI.nylon and other materials. Can mark black and white writing.

Instructions

1. Mix and use with additives, pigments, toners, and stabilizers without changing the original production process. Suitable for injection molding, extrusion, extrusion coating, blow molding, spray coating, and foaming.

2. The marking colors are black, white and gray.

3. The addition ratio is 1%~3%

Laser engraving powder tools have the following advantages:

a. Can make laser marking/coding on plastic surfaces smoother

b. Can be directly mixed with existing toners and formulas.

c. Does not have a great impact on the performance of the material;

d. Its lower addition amount reduces the cost of use;

e. Suitable for different types of laser coders.

Main Specifications

Serial number Item Technical indicators

1. Appearance: powdery, uniform color

2. Dispersion: no color spots or streaks

3 Heat resistance 200-300°C

4 Migration resistance level 5

5. Light fastness level 8

Note: Due to the different equipment used in the factory, the level of operating technology or changes in raw material formula and other factors, the final results will be different.

Features of laser engraving powder:

1) Save material costs and minimize your scrap rate;

2) High marking speed, active ingredients have very strong laser sensitivity and significant color change effect

3) Outstanding resolution, contrast, and gray price response: Laser-active microspheres can achieve good distribution in a small range

4) Most industrial laser marking systems with wavelengths in the range of 300NM to 2200NM can be used for marking operations.