Food Grade Polyethylene Granules For 85℃ Ultra Low Temperature Heat Sealing Film

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Finish | Smooth | Width | 1000mm |

|---|---|---|---|

| Material | Polyethylene | Film Type | Single Layer |

| Chemical Resistance | Excellent | Temperature Range | -50°C To 80°C |

| Certifications | ISO 9001, FDA | Tensile Strength | 5000psi |

| Elongation At Break | 300% | Application | Packaging, Agriculture, Construction |

| Length | 100m | Uv Resistance | Yes |

| Thickness | 0.5mm | Color | Transparent |

| Highlight | Food Grade Polyethylene Granules,FDA Polyethylene Granules,Food Grade Heat Sealing Polyethylene Film |

||

| Product name | model | Product color | Forming method | |

|---|---|---|---|---|

| polyethylene | ds308 | Natural color particles | Blown film molding |

Food Grade Polyethylene Granules For 85℃ Ultra-Low Temperature Heat Sealing Film ![]()

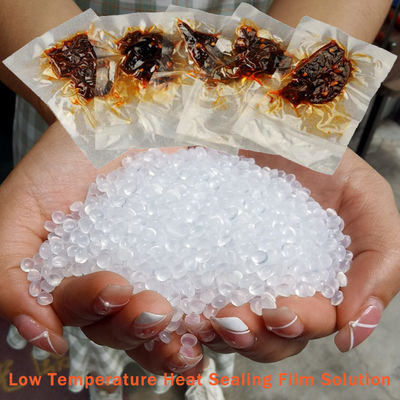

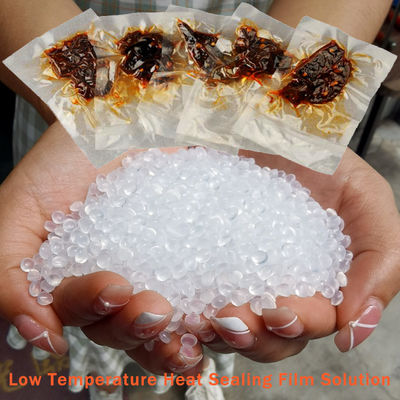

Provide low temperature heat sealing film solutions

Introduction to Guangdong Dingsheng low temperature heat sealing film polyethylene granules:

1. Polyethylene particles for low-temperature heat sealing films are a new type of packaging film raw material. The film is composed of three layers of composite films: a bottom layer made of polyethylene or polypropylene, a middle layer made of PET, BOPP and other materials, and polypropylene and other materials. surface layer. Low-temperature heat sealing film has good heat sealing performance and high transparency, and can effectively protect and display goods.![]()

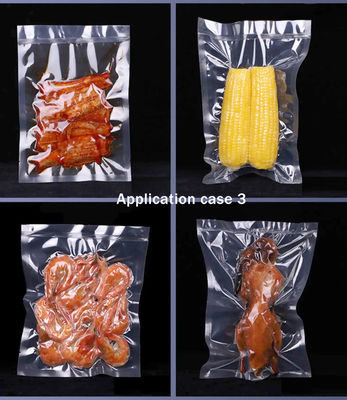

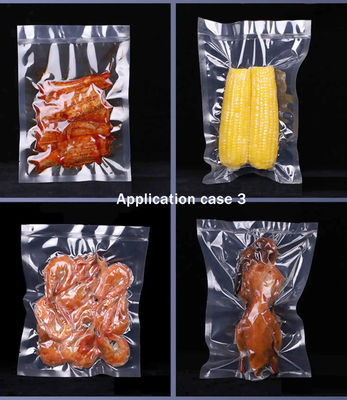

2. Application fields of low temperature heat sealing film

Polyethylene particles for low-temperature heat sealing films are generally used in sauce packaging and powder packaging, food packaging, pharmaceutical packaging films, cosmetic tubes and other fields. In the food field, low-temperature heat sealing films are used to package various candies, biscuits, sushi and other products, and can maintain the freshness and taste of the products. In the field of pharmaceuticals, low-temperature heat sealing films are used to package pharmaceuticals and medical devices and have good air tightness and moisture retention. In the field of cosmetics, low-temperature heat sealing films are used to package various beauty, skin care and makeup products.![]()

3. Characteristics of polyethylene particles for low-temperature heat sealing films

1. Low temperature heat sealing

The polyethylene particles used in the low-temperature heat-sealing film we produce can be quickly heat-sealed at a low temperature of 85°C. The film produced can be heat-sealed at extremely low temperatures to avoid damage to the product caused by high temperatures, while also improving production efficiency. , saving the heat sealing time of products and reducing energy consumption costs for enterprises.

2. High transparency

The polyethylene particles used in low-temperature heat sealing films produced by us have high transparency and good display effects in the production of low-temperature heat sealing films, allowing consumers to clearly see the products inside the packaging.

3. No odor

The polyethylene particles used in low-temperature heat sealing films are all food-grade materials and have testing standards. They will not produce odor during the production process and will not cause contamination to the products inside the package.

4. Moisture resistance and freshness retention

The products produced by low-temperature heat-sealing film polyethylene granules have good moisture-proof and fresh-keeping properties, which can effectively protect and maintain product quality and extend the shelf life of the product.

![]()

Low-temperature heat sealing film is a new type of packaging material with wide application prospects. It has the characteristics of low-temperature heat sealing, high transparency, no odor, moisture-proof and fresh-keeping. Our company has a professional R&D team that will provide better packaging solutions for food, pharmaceuticals, cosmetics and other industries.