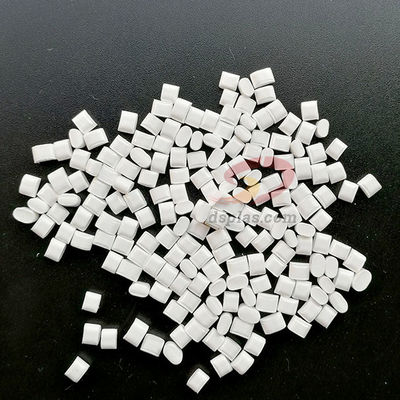

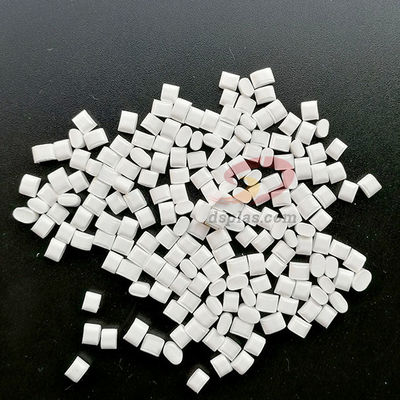

Laser Engraving PC ABS Particles Black Products Engraving White Words

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Density (23°C) | 1.18 G/cm³ | Melt Volume-Flow Rate (MVR) (220°C/10.0 Kg) | 20 Cm³/10min |

|---|---|---|---|

| Molding Shrinkage | 0.50 To 0.70 % | Flame Rating | HB |

| Highlight | Black PC ABS Particles,Laser Engraving PC ABS Particles,White Words PC ABS Particles |

||

Laser Engraving PC/ABS Particles Black Products Engraving White Words.

![]()

The laser engraving PC+ABS produced by Guangdong Dingsheng New Materials Company combines the excellent performance of laser marking and PC+ABS materials, providing high-precision, high-quality marking and decorative effects for various products. The following is a detailed analysis of laser engraving PC+ABS technology:

1. Technical principles

Laser engraving PC+ABS technology uses high-energy laser beams to engrave on the surface of PC+ABS materials. Through the interaction between the laser and the material, physical or chemical changes occur on the surface of the material, leaving clear and lasting marks. This technology has the characteristics of non-contact, high precision and high efficiency, and can realize the engraving of various complex patterns and text without damaging the material itself.

2. Technical advantages

High precision: Laser engraving technology can achieve micron-level engraving precision, ensuring the clarity and accuracy of markings.

High efficiency: Compared with traditional engraving methods, laser engraving technology can significantly improve production efficiency and reduce processing time.

No damage: During the laser engraving process, the laser beam only acts on the surface of the material, will not cause damage to the material itself, and maintains the original properties of the material.

Flexibility: Laser engraving technology can easily engrave various complex patterns and text to meet personalized customization needs.

Environmental protection and energy saving: There is no need to use chemical reagents and molds during the laser engraving process, reducing environmental pollution and energy consumption.

3. Application fields

The laser engraving PC+ABS produced by Guangdong Dingsheng New Materials Co., Ltd. is widely used in many fields, including but not limited to:

Electronic appliances: used for marking and decorating the casings and internal structural parts of electronic products such as mobile phones, computers, tablets, etc.

Automobile manufacturing: Marking and decorating auto parts such as dashboards, steering wheels, door handles and other parts to improve product recognition and aesthetics.

Medical devices: Mark and trace medical devices such as surgical instruments, medical consumables and other products to ensure product safety and traceability.

Daily necessities: Personalize and decorate daily necessities such as toys, stationery, tableware, etc. to meet the diverse needs of consumers.

![]()

![]()

![]()

![]()