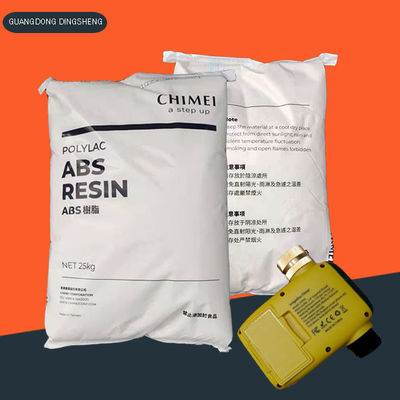

Chimei Polylac PA-777E ABS Plastic Particles Impact Resistant High Temperature Resistant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Tensile Strength | 45 MPa | Elongation At Break | 20% |

|---|---|---|---|

| Impact Resistance | High | Color | White |

| Flexural Strength | 60 MPa | Melt Flow Index | 6.5 G/10 Min |

| Density | 1.05 G/cm3 | Chemical Resistance | Excellent |

| Weather Resistance | Good | Processing Method | Injection Molding |

| Material | Acrylonitrile Butadiene Styrene | Heat Deflection Temperature | 120°C |

| Highlight | PA-777E ABS Plastic Particles,ABS Plastic Particles Impact Resistant |

||

Chimei Polylac PA-777E Impact-Resistant And High-Temperature Resistant ABS Resin

Product model: PA-777E

Features: High heat resistance, high impact resistance.

Product uses: home appliance casings, hair dryer barrels, auto parts, etc.

Often used in electrical appliance enclosures that require high temperature resistance.

Product Category: General Plastics

Material status: available from stock

Processing method: injection molding

Introduction to high temperature resistant ABS

High temperature resistant ABS is a modified material made by adding high temperature resistant plasticizer to Shouting ABS material. This material can maintain good mechanical properties and chemical resistance in high-temperature environments, so it is widely used in applications that need to withstand high-temperature environments.

The temperature resistance limit of ordinary ABS materials is generally around 70°C, while the temperature resistance limit of high-temperature resistant ABS materials can reach 90°C or even higher. This makes high-temperature resistant ABS widely used in the automotive industry, electronic appliances, home appliances industry, medical equipment and sports equipment and other fields. For example, heat-resistant ABS is used in the automotive industry for engine peripheral parts, radiators, fuel tanks, exhaust systems and other parts, because these parts need to maintain the stability of their structure and performance in high-temperature environments.

In addition, the injection molding process of high-temperature resistant ABS also requires special attention. Due to the hygroscopicity and sensitivity of ABS plastic to moisture, sufficient drying and preheating are required before processing to eliminate surface problems caused by water vapor and ensure the plasticizing effect of the plastic.

In short, high temperature resistant ABS is an engineering plastic with excellent performance and wide application, which can meet the needs of use in a variety of sound and temperature environments. When selecting for use, the appropriate material type needs to be determined based on the specific use environment and needs to ensure product performance and reliability.

![]()

![]()